Information for Students about Careers

I am occasionally interviewed by students whom I meet at aviation-related Facebook groups and subreddits or through activities like volunteering at schools or doing Young Eagle flights. When students ask me about aerospace engineering and flying, they often ask many of the same questions, so I thought I would put them - and my answers - on a single page. And here we are!

Click the links below to skip to each questions, or feel free to just scroll down and read them all.

• What does an aerospace engineer do? What is a typical day like?

• I don't like math. Does this mean that I should not become an engineer?

• What is the one thing that you wish you could go back in time and tell your younger self?

• Some thoughts on "Growth Mindset"

• What advice do you have for finding a job in aerospace?

• Should I get a Master's degree?

• How is work-life balance? Do you work crazy hours, weekends... or just 40 hours a week?

• Do you get to travel for work?

• How much work is done by yourself versus as part of a team? What is the work environment like?

• Why did YOU (Bernardo) decide you wanted to become an aerospace engineer?

• What have YOU (Bernardo) worked on, at each stage of your career?

Here we go...

I want to become a pilot...

What are the first steps towards becoming a pilot? Experiencing it!

If you're between the ages of 8 and 17, the first thing you should do is get a Young Eagles flight. Young Eagles is a program where pilots volunteer to give flights to kids. Many pilots do this, because they understand the importance of getting the next generation excited about aviation. The program is organized by the Experimental Aircraft Association. Kids who go on Young Eagles flights get a bunch of perks, such as free online ground school (the "book learning" part of becoming a pilot: learning about weather, airspace, airplane systems, how airport operations work, etc.). To get a Young Eagles flight, contact your nearest Young Eagles coordinator, or your nearest EAA chapter, or attend a Young Eagles "rally" (which is an event where many pilots agree to show up at a small airport in the morning and give a ride to any kid who shows up and asks for one). More info here.

If you're 18 or older, then... you can get an Eagle Flight (like Young Eagles but without the perk of free ground school afterwards).

If no one gives Eagle Flights or Young Eagle flights in your area... then go to a flight school and chat with an instructor. Most small airports have a flight school or two; Google "learn to fly" and the name of your town. The folks at the flight school will be happy to tell you about the training that is required to become a pilot: Number of hours of dual instruction (i.e. flying with an instructor), number of hours of solo flight, FAA tests, etc. If you can afford it, go flying with an instructor for half an hour or so. (In the US, this should be doable for just under 100 dollars).

That is definitely the ideal first step; to experience it, if possible.

Whether or not you go on a flight; Something else you can do right away, if you'd like to start learning the things you have to learn in order to become a pilot, is to take Embry-Riddle's free online ground school. Oh, and: The authoritative textbook for Private Pilot ground school - covering all the content that a person must learn in order to become a Private Pilot - is available online as a free PDF. It's the FAA's "Pilot's Handbook of Aeronautical Knowledge". It is surprisingly readable, presenting each bit of information in the simplest way possible, with tons of diagrams. Check it out.

Also worth pointing out is the fact that being a professional pilot does not require any academic credentials. Flight training, pilot "ground school", and earning the certificates required to become a pilot, are things done in parallel with academic studies, not at an actual school. (This is different from becoming a lawyer or a doctor, which do require specific academic degrees). Most commercial airlines flying large jets will require pilots to have a Bachelor's Degree, but it could be in Literature or Philosophy. So when people ask "What classes should I take if I want to become a pilot", the answer is: You don't really have to worry about it. That having been said; The things that a pilot must learn during flight training and pilot certification will make more sense if you have a good understanding of physics and math (so that you can understand the dynamics of flight: forces, loads, speeds, times, weights, angles, air pressure, and how things like compasses and navigational radios and GPSs work, i.e. when they work less than perfectly...), and to a lesser but still important extent, biology (e.g. what it means for a human body to be tired, disoriented, cold, hypoxic, sick, etc.) and chemistry (e.g. the stoichiometry of fuel-air mixtures, the reactions that lead to incomplete combustion, and how solutions and partial pressures work - which determine how clouds and fog and icing form and dissipate). And before you ask: Yes, you - YOU! - can learn all these things if you work at it.

However...

I would not recommend commercial flying as a career.

This is coming from someone who has been excited and passionate about airplanes and flying for his whole life, and who said "I want to be a pilot when I grow up" until I was a teenager.

Why did I change my mind? (Other than: Because being an engineer is actually cooler...)

In short: Because it is a very competitive job market. By this, I do not mean "It's difficult to find a job", although that is also true (especially in the wake of COVID). What I mean is: Lots of people really want to be pilots, so if you think about this from a supply-and-demand point of view, this means that airlines can make pilot jobs pretty crappy, i.e. low pay and long hours and extremely expensive training required before you're even eligible, etc. Most pilots start out flying smaller airplanes (turboprops, small regional jets, or cargo airplanes) for many years before flying large passenger jetliners. During those years, the pay is terrible and they don't get a lot of sleep (and most of it is not in their own bed). If you go to the airport to take a short flight (say, about an hour) in a small airplane, it's likely that your pilot earns a lower salary than the people working at the airport food court.

Yes, some commercial pilots have high pay and reasonable hours. They get there by flying for the same airline for over 10 years. Seniority determines which pilots get the best jobs. What if they get laid off (as pilots often do e.g. when demand for travel decreases) or their airline goes out of business (as they often do)? Then they gotta start all over! Back to flying turboprops for 16 hours a day for many years...

I fly for fun, as a hobby. This means I get to go flying whenever I want, for the express purpose of enjoying the view and maneu. I'm confident that, for a commercial pilot, things become more boring and "feel like work" more than when I go flying. It's true, flying single-engine piston-powered airplanes is not as prestigious as flying hundred-ton jetliners... but in some ways, it's actually a lot cooler and more fun.

What does an aerospace engineer do? What is a typical day like?

There are many kinds of aerospace engineers. A typical day for one of them will be very different from a typical day for another. And, as I discuss later: At a large company, each engineer only does one of these roles, while at smaller companies, each engineer has many roles - sometimes multiple ones in a single day!

Think about the "life cycle" of an airplane, as a product. (We'll talk about spacecraft in a minute). It's similar to any other commercial product, like a phone or a car. The process starts when a company (sometimes a small group of friends in a start-up, sometimes a massive multinational corporation) determines that, if they built an airplane with certain characteristics (e.g. size and range), it would probably sell well (e.g. to airlines, the military, private individuals, cargo companies like FedEx, or people who do certain specialized kinds of work such as surveying power lines or crop-dusting). Maybe that company is the first to have that idea, or maybe a new technology would now allow an airplane that is similar to current ones but better, e.g. more fuel-efficient or faster or safer. What happens next? How does that idea, for a future airplane that is better than any current airplane (for at least one job), become a reality?

First, some aerospace engineers do "preliminary design": How big should the airplane be? How much wing area will it need? How should those wings be shaped? How much engine thrust will it need? Where do we put the engines? Should the structure be aluminum, carbon fiber, or something else? Should the airplane have a conventional layout with three tail fins in the back or should it be something more unusual like a canard airplane or a flying wing? Engineers will evaluate the pros and cons of each choice, and arrive at a design that is most likely to do what the customers will want it to do as inexpensively and safely as possible. The design at this point will not be very detailed, pretty much a three-view drawing with maybe a few pages of description and some extra details. It will not specify what each little component is or where it goes. It's a sketch.

Engineers who do preliminary design are always looking at current airplanes and asking themselves: How would the capabilities of this airplane change if it had... a smaller tail? A differently-shaped wing? An alternative engine? What would have to be changed in order for this airplane to be able to carry a heavier payload, fly for longer, or get into and out of a short dirt runway? How could new technologies in materials and aerodynamics and engines be used to make airplanes better... by tweaking the design of current airplanes or by designing all-new airplanes? Preliminary-design engineers have to know a little bit about every aspect of airplane design, why each part is designed the way it is, and how the airplane is flown. From there, they basically do "physics problems" to calculate how much more wing area or curvature or engine power or whatever would be needed for the airplane to have a certain capability, how much the capability would improve if new features such as a new engine or better wingtips were added, and what the cost of this would be, i.e. whether or not it would be worth it. So they also have to have a little bit of an understanding of what the market is like, and of how much it costs to build an airplane.

If it's a new airplane, then a new wing was probably designed for it. Will that wing, sketched by the preliminary-design folks, really generate all the lift required to carry the airplane... while also generating minimal drag during high-speed cruise? And... at slow speeds so that the airplane can take off and land without needing two miles of runway? Some aerospace engineers are experts in aerodynamics, and will run detailed simulations and wind-tunnel tests to tweak the shape of the wing, to make sure it generates the amount of lift required even at slow speeds for takeoff and landing, and with minimal drag during high-speed cruise. They will probably try "experiments" with a wing that is a little thicker or a little thinner, a little curvier or a little flatter, flaps that are a little bigger or a little smaller, to find the "sweet spot" where the wing delivers the desired performance with minimal weight, drag, and cost. And it's not just the wing: They will check that the tail fins (which are in the "wake" of the airplane) and their moving surfaces are large enough to stabilize and control the airplane; They will check that the airflow around sensors is smooth enough to not disrupt readings; They will make sure that there is good airflow into the engine even if the airplane is flying at odd angles and slow speeds; They might try moving some small external features around (doors, antennas, lights, etc.) to minimize drag. This is mostly done on the computer using Computational Fluid Dynamics simulations, but usually a wind tunnel test is done at the end to check that a couple of the simulations (and, therefore, probably all of them) are accurate (or off by a knowable amount).

The initial decisions about structures, made during preliminary design, were really just educated guesses. Some aerospace engineers specialize in structures - in how to make each part of the airplane as lightweight as possible while still being able to take all the loads it might encounter in service, and without being too expensive. Each part of the airplane might require different materials, depending on whether it is hot, wet, dirty, and how it is loaded. Carbon fiber might be the lightest material for its strength, but it will come apart when loaded certain ways or if it's too close to the hot part of the engine. It's also expensive, so it's only worth the cost if it significantly reduces fuel burn, or if the airplane will be unable to perform its mission unless the structural weight goes down. Structures engineers use Computer Aided Design (CAD) software to design the structure in 3D, and various analysis techniques such as Finite Element Models to check that the structure is just strong enough to take the required loads (and not any stronger! As they say; "Anyone can design a bridge that stands up, but only an engineer can design a bridge that BARELY stands up"). They also work closely together with industrial/manufacturing folks, to make sure that the components being designed are easy to build and not too expensive. Sometimes, making the part a little heavier than necessary will reduce its cost significantly - such as an outer skin that should ideally transition from being thicker in a high-load area to thinner in a low-load area, but it's too expensive to thin down the sheet, so a sheet of uniform thickness (the thickness required at the thick end) is used to make the skin. So, again, most of the time is spent designing and analyzing the structure in software... but at the end, you design and run some structures tests to make sure that the structure can take the required loads (and not much more) .

And then, there are systems. What should the pilot's instrument panel be like? What should the autopilot be? What kind of battery should the airplane use? Should the control surfaces and flaps and landing gear move around by hydraulics or electrical power or just mechanical pushrods and cables? Most importantly: If each of those things broke, could the airplane still be flown to a safe landing? Systems engineers will select the right components for all those little jobs around the airplane, from a radar in front to the toilets in the back. Anything in the airplane that must perform a function, a systems engineer will determine how big and capable it has to be, choose a good one from the many companies that make these things (or ask for a new one to be developed, one that is bigger or smaller or lighter than previous ones), make sure that its failure will not cause a crash... and maybe run some tests to check that it fails as expected. So, systems engineers have large databases about all kinds of airplane components, an understanding of their capabilities... and they too sometimes run tests to check that everything works (or fails) as advertised.

Let's not forget maintenance! (I'll spend a little extra time on this because I did dedicate a lot of my career to it, and it is a generally under-appreciated field). The airplane might be perfect and beautiful on its first day, but nothing lasts forever. Maintenance means looking over every component in the airplane for signs of deterioration: fatigue, corrosion e.g. rusting, damage from hail, accumulation of dust or oil or other things that might catch fire, the disbonding or delamination of things that are "glued" together, wires becoming disconnected, pipes and hoses getting brittle, systems becoming less functional, etc... and then repairing, replacing, or refurbishing anything that has deteriorated to a point where it might be unsafe (or might become unsafe before the next maintenance check). The job of the maintenance engineer is to do analysis for each part of the airplane to determine how and how often it must be checked, and then create procedures for how each part must be repaired or replaced if it deteriorates or is damaged. The challenge is figuring out the least expensive maintenance procedures that meet all safety requirements and standards: For example, say that all safety requirements are met whether a certain part is inspected visually (which can be done quickly but might have to be done more than once a year) or checked with an instrument or sensor i.e. a machine (which takes time, training, equipment... but can be done once every few years). The maintenance engineer has to do analysis to determine what is the allowable level of deterioration of that part before things become unsafe, then how often you'd have to check it using each method (visually, or using various machines), then figure out which would be the cheapest... then write up a document that explains how to do this, step by step, and how often. Same things for figuring out how to repair an airplane if it is damaged by a fire, or if another airplane or a ground vehicle hits it, if the pilot hits the tail (or the wingtip) on the ground during takeoff or landing, etc.: The maintenance engineer has to design a set of modified airplane parts that will "patch the hole", that will restore all the internal connections between all the things that were connected to each other before the damaged material is removed, that will be strong and air-tight and not too heavy or too draggy, etc. The process of designing a repair is similar to designing the original airplane parts, taking into account the structural loads, manufacturability, systems functionality, and so on. Doing maintenance properly (both when it comes to the natural "aging" of the airplane, and also addressing unplanned incidents like impact damage) is absolutely critical for safety, because many airplane accidents have been caused by maintenance mistakes. Optimizing maintenance is also critical for the economic viability of the airplane as a product, and of the airline or maintenance shop as a company: Doing maintenance over the lifetime of the airplane (often 25 years or more) is a significant part of the cost of owning and operating an airplane, so it is important to be able to reliably predict in advance that a new airplane will require less maintenance over its life than previous airplanes, and that it will be more easily repairable if necessary. As with the other engineering disciplines discussed above, computer software is used to figure out how and when each airplane component might deteriorate (and thus how much maintenance it will need) given its materials, manufacturing processes, loads, temperature, corrosive environment, the statistical performance of similar components in the past, and factors that might cause this one to "age" faster or slower than previous ones.

(It's important to note that, in the United States, a maintenance engineer is someone who does what I described above - i.e. analyzing repairs and maintenance actions to make sure that they are strong, durable, functional, economical, and meet all safety requirements, and then writing up a step-by-step document about how to do it on the airplane - while the people who actually physically "turn wrenches" and work on the airplane hands-on are called mechanics. However, there are countries where mechanics are referred to as "maintenance engineers", so when someone says "maintenance engineer", they might be from a country where this is not actual engineering! Do keep this in mind. And then there's the term "technician": In some companies, technicians do engineering work that is only slightly less complex than what is done by "real engineers", while in some other companies, technicians do hands-on "turning wrenches" work, even in the US. Apologies for the inconsistent vocabulary, but things like this exist in almost every industry. "What does 'X' mean? Depends whom you ask...").

The end result of all this work designing, analyzing, and testing various aerodynamic shapes, structural parts, and systems: A large collection of engineering drawings ("blueprints"... or 3D CAD models on the computer) that specify the exact shape and location and manufacturing processes for each component of an airplane, as well as manuals for how to fly it, how to maintain it, etc. These are handed off to the folks in the factory, the machinists and technicians and mechanics (as well as other companies, who make things like engines and lights and cockpit displays and sometimes big parts of the airplane like the landing gear), who then actually fabricate components and assemble them into an airplane. The engineers will keep an eye on that process, to make sure that it is actually possible and practical to build the airplane that they designed. The design may have to be tweaked in order to make it easier for things to come together in the factory.

And then, once the airplane is designed and the prototype is built, there is flight-testing! This is arguably the most glamorous and exciting part of aerospace engineering: Flying the new prototype through all kinds of extreme maneuvers and conditions, to make sure that it flies as expected and that things don't break. Flight-test engineers will plan a series of flights that cram the highest number of relevant tests into the shortest amount of time, will do analysis or run simulations to predict what all the sensors should say during each test, and will look at the data immediately after each test to make sure that it matches predictions - and, when it doesn't, to figure out why, and what do to next (e.g. change something on the airplane, test again). Flight-test engineers sometimes get to ride along in the prototype, to follow things in real-time. Many flight-test engineers are also pilots, so they can quickly improvise with the test pilots, and come up with ideas for how to immediately re-do a maneuver in a slightly different way in order to get better data about how the airplane flies.

Once the airplane is shown to work properly and safely and efficiently (and this might involve tweaking the design a little bit, in case testing reveals unexpected surprises), it is a commercial product! You can buy one! But the engineering isn't over. That's just the first version of the airplane. Operators (the people or companies that fly the airplane) will probably eventually want a slightly bigger one, or one that can fly farther, or one that can take off and land on shorter runways, or the military might want one that can carry weapons or large sensors or antennas... so this whole process repeats, except instead of inventing a whole new airplane, the engineers create what is called a "derivative" airplane. This means that it's just like the original version, except some things are changed in order to enable the new capability. For every new airplane, there will probably be many derivatives, so realistically, most aeronautical engineers spend most of their time on derivatives, i.e. on designing and analyzing changes to current airplanes' structures, systems, aerodynamic surfaces / exterior features, maintenance practices, and manufacturing techniques.

Sometimes these changes are not for a derivative, as much as for making a current model slightly better. Maybe, once the airplane enters service, it turns out that a component keeps fatigue-cracking, or the flight control system is prone to a dangerous kind of malfunction, or the new batteries can spontaneously burst into flames, or one component is too easily bent during hard landings, or the cockpit is poorly designed in a way that causes pilots to keep spilling their coffee onto the engine controls... and so the design must be tweaked. This is the job of the sustaining engineers. They sometimes refer to themselves as "problem of the day" engineers, because they never know what surprise will require their attention when they come into work in the morning... and whether it can be fixed by some quick research and paperwork and redesign/analysis on the computer, or if it will require the fleet to be grounded while an extensive redesign is tested and implemented.

And finally, let's not forget the other kinds of engineers that work at airplane companies. We talked about all the software needed to design and analyze airplane components and systems, the databases of subsystem parts and suppliers and test data, the sensors recording data during flight-test... You need software engineers to write and maintain all that code. You need flight-operations engineers to calculate the most efficient route for flying an airplane from point A to point B. You need certification engineers who understand exactly what the FAA wants to see when it comes to showing that the airplane is safe, and who know how to request tests and write reports so that the required data is generated and communicated as efficiently and effectively as possible.

Arguably the most important non-aerospace engineer at an airplane company is the manufacturing engineer, industrial engineer, and/or tooling engineer. When a new (or modified) airplane is designed, they design and help to build and run the new (or modified) factory for it. They know about the most reliable and cost-efficient ways to make each kind of airplane part, from carbon-fiber skins and aluminum beams to windows and flap mechanisms. They know the best way to assemble the wings, join them to the fuselage, put together the cockpit instrument panel, and mount the engine. The cost of a commercial product (e.g. the cost of your phone or your car) is, to a great extent, determined by how efficiently the factory operates. So a good industrial engineer will mean the difference between an airplane that is way too expensive, and an airplane whose price is attractively lower than its competitors'.

As for spacecraft... all of these things also happen on rockets, satellites, space capsules, space stations, space probes, etc. There are two huge differences.

The first difference is that most spacecraft are one-offs. There is only one International Space Station, only one Hubble Space Telescope, only one Mars Curiosity Rover. Sometimes there are a few: a few Space Shuttles, a few missions to the Moon, about thirty GPS satellites... It's relatively rare that a spacecraft manufacturer (SpaceX, Boeing, Lockheed, Northrop...) sets up a factory and cranks out multiple copies a year, the way that manufacturers do for airplanes and cars and phones and so on. (The only exception that I can currently think of are SpaceX's hundreds of StarLink satellites). This means that engineers are usually working on all-new designs more often, which do take into account the lessons-learned from previous spacecraft, but usually not any of the exact same components, because new technologies are always being incorporated. This means more testing, in the lab and outside... and a higher failure rate, i.e. more surprises from tests that require redesigns.

That gets us to the second huge difference: Once a satellite or a space probe is sent out, it will never be touched again by a human. EVER. There are a couple of exceptions to this, such as the Hubble Space Telescope, but in general, satellites and space probes (including landers and rovers) have to work perfectly with ZERO maintenance to their hardware. The level of reliability required is just insane, especially given the extreme temperatures and pressures and radiation levels that these little orbital (and, sometimes, surface) robots have to survive. That's another reason why they test the heck out of each new spacecraft before sending it up. By the time the thing is launched into space, it has to work perfectly, for years, without anyone ever touching it again.

There are a few more questions below about the day-to-day work life of an aerospace engineer, such as work-life balance, different kinds of work environment, and differences between large companies vs. small ones. See below.

What advice do you have for a high-schooler who is interested in possibly becoming an aerospace engineer?

Classes (This almost goes without saying): Take all the STEM classes that you can, at a level that is as advanced as possible (e.g. AP, IB...), especially physics and math. Yes, you can do it; Scroll down to here to read some of my thoughts about taking tough classes.

Hobbies: There are many hobbies that will teach you the kinds of things that will make you a better engineer and make it easier for you to learn engineering (and math and physics).

- The best one is definitely flying! (You can solo a glider at age 14 and a powered airplane at age 16). More info here. However, realistically, this is too expensive for most teenagers.

- Next on the list is building and flying remote-control airplanes. (No, not multicopter drones, which stabilize themselves in flight and require no building. Those are better than nothing, I guess, but they will not teach you much). RC airplanes used to be expensive, but prices have gone down drastically in recent years. If nothing else, please check out Flite Test's YouTube channel; They create and fly some outrageously creative and fun RC inventions - and they sell many kits that are perfect for a beginner. Also check out Power-Up, which is a tiny electronics package that allows you to turn paper airplanes into RC airplanes that can be controlled from a smartphone. (Warning: That is much harder than it sounds! I'd go with a larger RC airplane at first, if you can afford one at all. Again, they're not crazy expensive).

- It's worth spending some time getting good at flight simulators, such as X-Plane or (of course) Microsoft Flight Simulator.

- However, the best thing towards becoming an engineer - about as good as flying real airplanes or making RC ones - is to modify and create airplanes for flight simulators. X-plane has a "Plane Maker" feature that makes this relatively straightforward. If you do research into the meaning and background behind each of the options that you can tweak in the airplane you create, you will learn many key principles in aerospace engineering. Some real airplanes were designed, "flown", and improved inside Plane Maker before being actually designed and flown. That kind of computational power used to only be available at large aerospace companies, but now you have it at your fingertips! (as well as lots of YouTube tutorials about how to use it).

- If you're more into the "space" side of aerospace, of course there is Kerbal Space Program.

Getting into college: As a high-schooler, your main job (especially if you want to become an engineer) is to work towards getting into a good college. This means getting good grades (and getting help from your teachers, YouTube, other websites, book, and/or other resources as necessary in order to make that happen), doing well on standardized tests (and getting help from test-prep books... and/or other resources as necessary in order to make that happen), and getting good at writing application essays (and, if necessary, getting help from your college counselor and/or from college admissions coaches, many of whom volunteer their services for free). There is a whole industry dedicated to helping high-schoolers with getting into good colleges. All I can say is: Take their advice!

Choosing a college: There are a lot of ways to choose what college is best for you (e.g. looking at rankings of the best engineering schools, applying for scholarships, thinking about where geographically you'd like to live, deciding if you'd rather go to a small school or a large one, making sure the college's engineering program is ABET-accredited...), so I will offer only the one good piece of advice that I almost never see out there but that made a huge difference for me personally and for most people I know: If possible, try to attend a college that has opportunities for undergraduates to do research. If you have narrowed your list down to several colleges, try to find out whether each of them has an undergraduate research program, be it university-wide or just within each engineering department. Many colleges have programs that will pay an undergraduate to live on campus for the summer and do research. I did this when I was in college and it was one of the best experiences I've ever had. And if you do end up going to a college where undergraduate research opportunities are not plentiful, many top-notch colleges such as Stanford have programs where undergraduates from other colleges can come spend the summer and do research, so I would highly recommend you look into that when you get to college. More details below, in the next question (about college).

One last thing: I wrote a book, specifically for students, about the most interesting and innovative work currently being done in aeronautical engineering. The PDF is available online for free. Check it out. Hopefully, it will help you appreciate that there is lots of cool work currently going on to make the airplanes of tomorrow superior to the airplanes of today (electric airplanes, solar power, supersonic transports, airplanes that fly into space and back, flying cars that fly themselves and that can take off and land straight up and down like a helicopter, drones the size of insects, robotic stealth fighter jets that do not carry a pilot and thus reduce the risk to human life in battle...) and that you could be a part of that!

What advice do you have for a college student who is interested in possibly becoming an aerospace engineer?

My number one piece of advice would be to try to get involved with undergraduate research. As a researcher, you can be a real working scientist, working to expand the limits of human knowledge in fields such as aerodynamics, propulsion, structures/materials, automation/AI, manufacturing, and other things that could eventually make the airplanes of the future more efficient, safer, less expensive, easier to fly, etc. Working in a lab was one of the most fun jobs that I ever had, with the freedom to prototype and try out new ideas, surrounded by smart and creative academics pursuing their own ideas, a great combination of hands-on work (making and testing stuff) and analysis on the computer, the opportunity to present at conferences and publish academic papers... It's super cool, and will help you stand out when you're applying for jobs later. So, how do you get started? Look up professors in your schools who do research in areas that interest you or in areas that sound aeronautical-related, and ask them if they'd be willing to hire you to work in their lab either part-time during the school year (at the very least as a volunteer) or during the summer. Or, if you have an advisor and/or if some professors taught a class that you think is really cool, ask them if they have or know of any opportunities for you to help out with research activities. One last recommendation: many top-notch colleges such as Stanford have programs where undergraduates from other colleges can come spend the summer and do research. Apply to those too!

Make sure you get involved with student groups, or even better, start one. Employers will want to see that you did things other than go to class, and it is especially impressive if you have had leadership positions (not necessarily running the whole club, but maybe leading a small team or being an officer such as treasurer). The best are design-build-fly competitions, clubs around remote-control airplanes or drones, model rockets, flight simulators, and other activities related to aerospace engineering. In short: Either join your school's AIAA Design Build Fly team (and do it for more than one year so that in your second or third year you can be "lead aerodynamicist" or "lead structures engineer" or whatever, which means you help one or two new kids learn how things work) or start one if one does not already exist.

Also great are robotics competitions; There are tons of them, many of them at the college level.

Here is a controversial piece of advice: Major in mechanical engineering. Below (in the next question, about majors), I'll explain why.

Make sure you learn about the industry! Here, I write more about this.

One last thing: I wrote a book, specifically for students, about the most interesting and innovative work currently being done in aeronautical engineering. The PDF is available online for free. Check it out. Hopefully, it will help you appreciate that there is lots of cool work currently going on to make the airplanes of tomorrow superior to the airplanes of today (electric airplanes, solar power, supersonic transports, airplanes that fly into space and back, flying cars that fly themselves and that can take off and land straight up and down like a helicopter, drones the size of insects, robotic stealth fighter jets that do not carry a pilot and thus reduce the risk to human life in battle...) and that you could be a part of that!

Would it help or hinder my chances of getting a good job if I major in: aeronautics, aerospace engineering, mechanical engineering, industrial engineering, materials science, physics...

I actually recommend Mechanical Engineering as a major, rather than aeronautics/aerospace.

The reason: It's much easier to get a job. When you study mechanical engineering, almost everything you learn is applicable to the design, testing, manufacturing, maintaining, and improvement of aircraft... and of anything else that is made by humans. So, if the aerospace industry is experiencing a temporary down-turn when you graduate (which it does once every 10 years or so), you can work for a few years as an engineer on... cars, sports equipment, medical devices, electronics hardware, toys, buildings / infrastructure, home appliances, boats, furniture, you name it. So, with a mechanical engineering degree, you are qualified to work on literally any kind of physical product that you can imagine. That's because, when you study mechanical engineering, you learn a little bit about all kinds of engineering topics: fluid mechanics (i.e. aerodynamics, i.e. lift and drag), thermodynamics (i.e. propulsion, i.e. more powerful and efficient engines), control systems (e.g. autopilots and automated engine controls), structures (i.e. how to make each part of an airplane as lightweight as possible, given the loads it must withstand), manufacturing (i.e. how to make each part of an airplane as inexpensive as possible, given the reliability and quality requirements), electrical engineering (most airplanes contain miles of wires that do all kinds of things), dynamics (the loads required to maneuver an airplane, which determine the size and location of stabilizer fins and control surfaces), mechanisms (the most efficient way to design linkages and hydraulics for flaps, landing gear, control surfaces, engine parts, doors...), design (i.e. CAD e.g. SolidWorks), engineering drawing (i.e. how to tell the people in the factory how to make airplane parts), engineering writing (i.e. how to explain to the FAA that it is safe to certify your airplane, how to explain to a systems supplier exactly what you need their autopilot to do), computer programming (useful when reducing i.e. "digesting" tons of data from tests, and when automating repetitive processes such as simulating dozens of similar components such as the aerodynamics of a family of flap designs or the fatigue-cracking of a family of stiffener beams... see the question below about learning to code), etc.

Like I explain below in the questions about Master's degrees: Even after working at Boeing for over 10 years, I decided to get a Master's... in mechanical engineering. I do stand by this advice.

On the opposite end of the spectrum (so to speak), people sometimes ask me if it's possible to get an aerospace engineering job if your degree is in physics, math, materials science, etc. It depends on the company. For example, Boeing does require you to have an engineering degree in order to be an engineer. What this means in practice: People who do not have engineering degrees (e.g. who studied physics, math, etc.) must work in positions like "researcher" or "technician / technical designer"... until they get an engineering Master's (which can be done online in as little as 13 months, and Boeing will pay for it). Exceptions can sometimes be made, e.g. people with materials science degrees can work as Structures engineers. I know several people who majored in physics and went on to become aerospace engineers (three at Boeing, one in a smaller airplane company, one in a research lab... and only the Boeing ones had to then get engineering Master's degrees).

One last thing worth mentioning is industrial engineering / manufacturing engineering. It has interesting pros and cons. The main con is that many companies will only hire industrial engineering graduates to work as industrial engineers, i.e. to help them figure out how to improve their factories, how to manufacture airplane parts in ways that are less expensive and/or more reliable, how to design and build and run a new factory for a new airplane model, etc... i.e. not to work on the design of the airplane itself. (An industrial engineering graduate could work as an aeronautical engineer if they have additional experience designing/testing airplane-related things, such as at internships or while doing research or in hobbies... but it will be harder for them to get that job, all things being equal, that someone with an aeronautics/aerospace/mechanical engineering degree). The main pro is that it is easier, less academically rigorous, requiring little to no math beyond a 7th-grade level... so the easiest way to get an engineering degree is to study industrial engineering. However, this means that industrial engineering degrees have a bad reputation, since they are often chosen by people who don't want to learn the more difficult topics required for aeronautics/aerospace/mechanical engineering. On the other hand, industrial engineering classes tend to cover management-related topics that are important to any engineer but that are often not included in other engineering degree programs: project management, production management, supplier management, quantifying and assessing risk, calculating optimal strategies for things like pricing products and ordering supplies and allocating work between different people/places and setting up logistics around transportation... It is unfortunate that the first time I took classes about these topics was when I signed up for a few industrial engineering courses as part of my mechanical engineering Master's, by which point I had already been working as an engineer for about 10 years. I wish I had learned that stuff earlier! It is extremely valuable in making airplanes less expensive, which - as with any other product - helps to increase sales.

I don't like math. Does this mean that I should not become an engineer?

On the one hand: When you become an engineer, computers do nearly all the math for you, crunching large matrices for finite element analysis of structures, solving differential equations numerically for fluid-flow problems, finding optimal flight routes using brute-force trial-and-error (with sometimes a little machine learning thrown in) rather than using calculus of variations, computing areas and volumes, etc. So, most engineers do not actually need to perform math beyond the high-school level. Exceptions are engineers who work in narrow fields such as developing new analysis methods and developing/improving analysis software

On the other hand...

1) You do need to pass some relatively tough math classes in order to become an engineer.

2) A good engineer has an understanding of the math that the computer is performing and an expectation of what the answer should look like, so that if a mistake was made while the inputs were being entered, the engineer will spot a wrong answer right away (or understand why the computer returned an error, i.e. in what way it was asked to solve an impossible or computationally impractical problem) and fix the inputs accordingly. Good engineers don't just plug numbers into software and trust the outputs uncritically. They have enough mathematical intuition to think not only "This answer is probably wrong" but "Let's change the inputs a little bit to check that the output changes the way that I would expect" and "Here is a way to re-formulate this analysis that will make it far easier for the computer to solve quickly / solve at all / give me a more accurate result".

3) You can learn more math than you think you can. I know what it's like: All it takes is having one bad teacher one time, who did not do a good job explaining one concept, and then nothing ever quite makes sense again because all the future concepts that build upon it never feel quite solid or intuitive in your mind. This happens to most people. But, good news: There is hope! You can ask people (e.g. good teachers) for help, and you can teach yourself by reading books or watching YouTube videos by various people who are much better at teaching math than your one bad teacher (or even better than many of your good teachers). Feeling like you don't get advanced math concepts just means that you don't get them YET, and that if you put in the work, you can catch up and be as good at math as anyone. It's not easy, but it's definitely doable, and you'll be glad you did. Like many other life skills (such as running, cooking, playing an instrument...), it's worth putting in some painful work for a couple hours a week, so that after a few months, you have the skills required to do extremely impressive things that used to seem impossible. If nothing else, remember that your brain is like a muscle, and it can be made "stronger" if you exercise it the right way.

Trust me, you can learn math if you want to. Just find the first concept where things stopped making sense, re-learn that (get help and/or watch YouTube videos), and keep going up from there. That brings me to...

What is the one thing that you wish you could go back in time and tell your younger self?

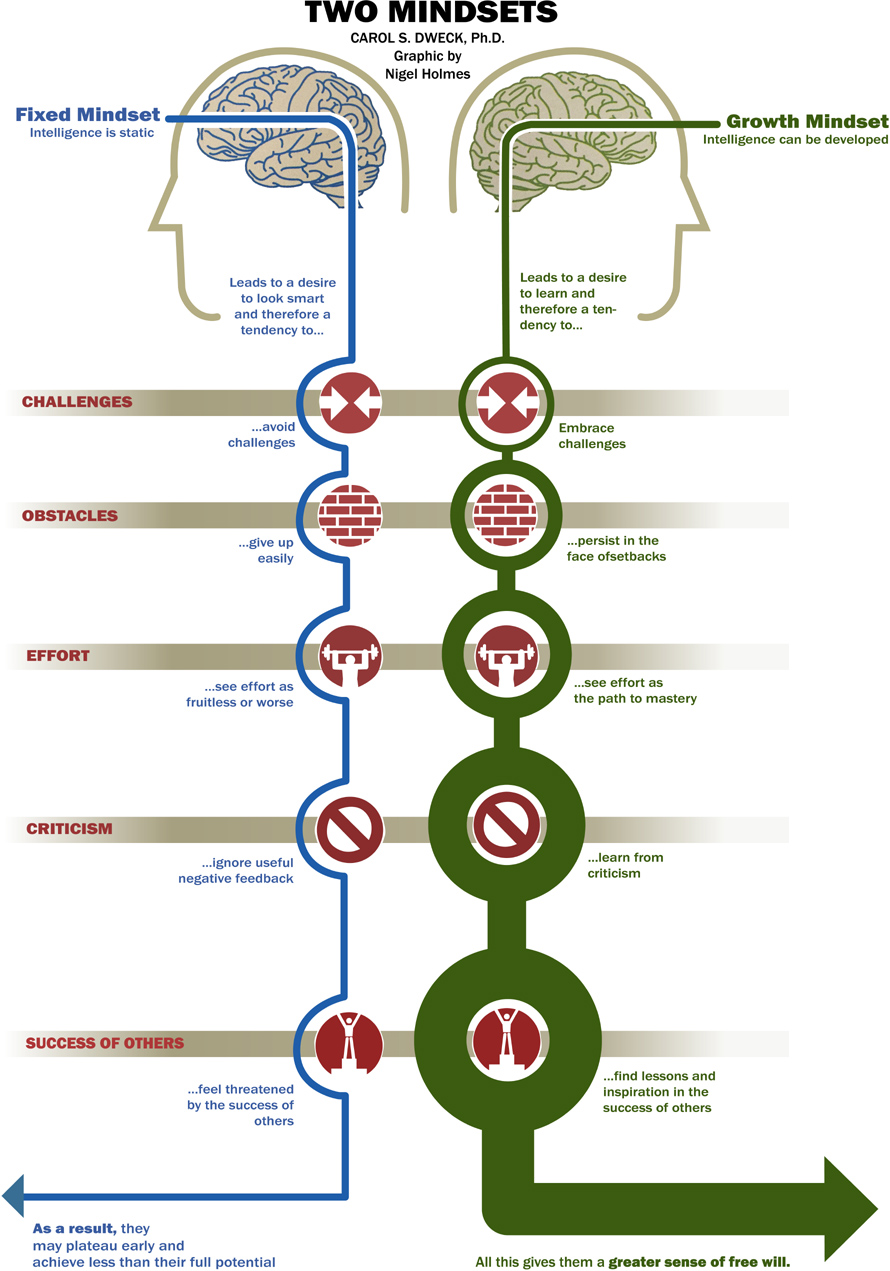

If I could go back in time and tell my younger self one thing, it would be to learn about the growth mindset, e.g. read this article and watch videos like this and this. For a quick summary, see below.

Some thoughts on "Growth Mindset"

I'll say it again: If I could go back in time and tell my younger self one thing, it would be to learn about the growth mindset, e.g. read this article and watch videos like this and this. Let me give you a quick summary:

A "fixed mindset" refers to a way of thinking about skills and abilities (and about other people's view of you) as mostly dependent on innate talent: Some people are good at certain things, some people are not. Folks with a fixed mindset avoid asking "stupid questions" because they feel embarrassed, and when they encounter an activity that they don't quickly succeed at, they avoid it in the future because mistakes make them feel (or look) "stupid". They prioritize "looking smart".

On the other hand, a "growth mindset" refers to a way of thinking about abilities as dependent on work, practice, perseverance, and the willingness to keep trying after failure. Folks with a growth mindset see failure as something to learn from so you can get it right next time, and ask all the questions they can think of because they realize that no one started off knowing the answers, everyone had to learn at some point.

The "growth mindset" has been proven by psychological and neurological studies to be accurate. It sees the brain as being like a muscle: Exercise it the right way and you can make it stronger, increase its capabilities.

The way to succeed at a tricky course in school or a difficult new job is the same way you get better at a sport: Find a coach and work on the areas where you are weakest until you become stronger in those areas. Tell them "You're gonna need to explain this to me". Practice, and repeat the hardest parts over and over. It's painful, but that's how people grow their capabilities.

What does this mean for engineers?

Two things:

First: When you're in school and you're struggling with a class, don't give up, do NOT think "I am not good at this". Go to your teacher, talk about what you're struggling with. Do more example problems, maybe look up additional lectures on YouTube or explanations in different textbooks. Do not be embarrassed to ask "stupid" questions. They are not "stupid": Nobody was born knowing this material. (If they were, then there would be no need for a class, textbooks, etc.). Just remember: When you are struggling with a class, you CAN learn the material and ace the test if you're willing to put in the work and to get help. Do NOT be embarrassed to ask for help.

Secondly: When you're at a new job, people who have been there for a while will refer to various things (acronyms, concepts, documents, analysis methods, historical examples) in a way that might sound like they expect you to know what they mean. DO NOT be afraid to say "What does that mean?" or "I'm afraid you're going to have to explain this to me". You may feel that such questions make you look stupid, but it's quite the opposite: They show that you are curious, that you are growing. Besides, experts love to get to explain a topic that they know a lot about, not just because they think the topic is interesting, but also because if you learn it from them, then you are "on their side", you know it "right". Again, nobody was born knowing all these things, everyone has to learn. You may think that an expert incorrectly guessed that you are probably familiar with a topic... But, in reality, experts simply forget all the time that the vast majority of people had never heard of the thing they're talking about, because it's such a big part of their work. When you remind an expert that their knowledge is not common, they will probably be happy about it ;]

In short, what this means for you: In school, when you're struggling, ask for help. (Not doing so would mean wasting all the education you got up to this point). And, at work, when you don't know what something means or what it's all about, ask. (Not doing so would mean wasting an opportunity to become a better engineer).

Below is my personal story for why I say that this is so important. (Feel free to skip this if you want).

I'll split it into three parts.

Part 1, in school: I had always been a smart kid, always got stuff right away in class, never really had to study, always got good grades, was always told I was "smart"... until I hit some really tough classes towards the end of my undergraduate years. I was too embarrassed to raise my hand in class and ask a question, because I was afraid that everyone would think that I was stupid. I'm not sure why I didn't go talk with the professor or the TAs during office hours, whether I was being lazy or embarrassed. As a result, I got terrible grades in those classes, had to retake a couple of them, and this badly hurt my GPA and made it harder to get into grad school (and prevented me from learning some useful concepts until later).

Part 2, at the start of my career: At school, whenever a concept was mentioned, that's because we had been exposed to the concept in earlier lectures or in the reading. I always basically knew what the teacher/professor was talking about. But when I became an engineer, I observed that when I asked about something, the answer always included concepts that I had never heard of before...and they were stated in a way that seemed to expect that I would be familiar with them. I was afraid to look stupid, so I did not say "Actually, we need to go back one more step. Could you please explain to me what that means?". So, during my first year or so working as an engineer, I was given more and more new tasks, but over and over again, I failed to learn the background information that I would need to do those tasks.

Part 3, one year into my career; one of the darkest times in my life. People had been telling me all my life that I would be a great aerospace engineer, but I was terrible at it. I couldn't quit and disappoint my parents, family friends, teachers, and everyone at my university. What could I do? I was spiraling into depression... until I received in the mail, as if from the gods, a magazine (that I subscribed to) with an article about growth mindset. Suddenly, I understood exactly what the problem was, as well as the solution: As stupid questions, as painful as that may feel. Starting at that point, whenever someone gave me an explanation that contained a mysterious acronym or that referred to a document or a program or an event that I was not familiar with, I clenched my teeth and cringed and said "Actually, I don't know what this means... and could you give me the background on this?". The change was night and day. People never thought I was stupid (because, again: Experts like explaining things, they know that nobody comes in with all this knowledge, and they saw me as "on their side" when it comes to how to do things "right") and I learned enough to do my job. I became (gasp) a good engineer! This skill, of cringing and asking "stupid" questions through gritted teeth, served me very well at each new job, and during grad school and during flight training.

Again, if I could go back in time and tell my 20-year-old self one single thing, it would be this. Ask the stupid questions, whenever someone says something and you don't understand it. Nobody will think you're stupid; People will know you are growing.

Should I learn to code?

If you get an engineering degree, you will almost certainly learn how to code at some point for a class, even if it's writing simple scripts on MatLab.

But... Yes; The sooner you learn to code (and especially if you do it "for fun", before you really have to), the easier it will be when you really need to know how. This is especially true now that there are so many resources (books, toys, YouTube videos) for people who want to learn.

That having been said: Some good engineers, especially older ones, do not know how to code. So it's not strictly required. (On the other hand, such engineers are thought of similarly to how you think of old people who do not know how to use computers...)

Two examples of the kinds of work where aerospace engineers need to code:

Example 1: If you run a test, you'll get tons of data. There will probably be several sensors on the test, and they'll be capturing data at many times per second. Each data point will be a number, which probably corresponds to the voltage drop or current or resistance across the sensor. For each data point, you'll need a simple equation to convert that to the thing that the sensor is measuring: a pressure, a strain, a temperature, a force, an acceleration, etc. Often, that will not be the actual thing you care about: maybe what you want is the stress, or the location... which means taking each value from the sensor and putting it through yet another equation. Good; Now you have actual data! But you'll still want to remove outliers, remove noise, and do other things that require some kind of statistical analysis (at the very least "take the average of this data point and the previous six" or something like that). Maybe you'll want to delete every point that is above some value, or below some value. Maybe you'll want the difference between each point and its predecessor because you care about the rate-of-change. Maybe you only want to include points that are between certain values AND from times when the data from this other sensor is between a certain other set of values. Et cetera. And you have to do this to maybe tens of thousands of data points, not just 20 or 30. So you'll probably want to write a simple computer program to do all this for you. MatLab, and Visual Basic (i.e. macros in Microsoft Excel) are the most common ways of doing this kind of thing.

Example 2: Say that you're creating and running a simulation; Maybe you want the stress field around a structural component of a certain shape when it's loaded a certain way and has a hole in it (for a screw or a rivet), maybe you want to understand the airflow around a flap or a winglet. So you create the thing in 3D and run your simulation. But now, you want to know how the results change as a function of one or more parameters. Maybe you want the stress around that fastener hole as a function of its diameter and of how close it is to the edge or to the next hole; Maybe you want the pressure around that flap as a function of its deflection angle and of the height of the slot (gap) between it and the back edge of the fixed wing skin. "Testing" for just four values for each of those parameters would mean sixteen simulations. (Imagine a four-by-four table, where each column is for one value of one parameter - say, the flap angle - and each row is for one value of the other parameter - say, the gap height. There are sixteen combinations). Do you create sixteen 3D models from scratch? No, you write code to do that for you. (And once you write the code, it's not that hard to make and run 400 models instead of 16, if you want to really find the "sweet spot"/"worst case" combination of factors). Many of the software programs that do this kind of 3D simulation allow you to create models via intuitive graphical interfaces... but each button you press, each click of the mouse, and each value you enter, is saved as a line of Python code. So once you're done making the model and setting up the analysis "by hand", you can open up the Python file that lists all the things you did. You can then change it to make models that are similar except in one small detail... But that will probably break the script, unless you know a little bit about Python programming. And once you know how to edit that Python code, you can actually ask the computer to quickly make models that are better than the one you would have made by hand (because you can copy and paste chunks of code to make the computer do something over and over, instead of spending hours doing something over and over yourself). You can also easily write a script that outputs multiple models for analysis, i.e. that changes the numbers for you. (So instead of creating 400 copies of the Python file and changing the values in each one, you create a single file that loops i.e. cycles through all the 400 combinations of values). It's powerful stuff. People earned whole Ph.D.s in the 1990s by doing parametrized simulations that I could easily do today in an afternoon!

What advice do you have for finding a job in aerospace?

There's lots of good advice out there (e.g. about the importance of networking) and I won't repeat it all here.

I think the main bit of advice that I have to add to the conversation is: Learn about the industry. Learn about small companies. Read and magazines like Aviation Week, follow the various blogs and Facebook pages that keep track of sectors of the industry such as electric VTOL "flying taxis", homebuilt experimental kitplanes, UAVs, etc. Go to the webpages of small companies and apply for jobs there; companies like Scaled Composites and AeroVironment (which, yes, belong to Northrop, but are fairly independent subsidiaries), CubCrafters and Sonex, Vashon and Glasair, Wing and KittyHawk, Kratos and General Atomics, Opener and Wisk, Insitu and Dynetics, MagniX and Ampaire and Eviation, Boom and Aerion, Cessna and Beechcraft and Cirrus... and those are just a few that come to mind, because they've all been doing some very cool work. I didn't even have to look up the lesser-well-known makers of these respective products (kitplanes, LSAs, UAVs, eVTOL prototypes, electric airplanes, single-engine airplanes...). Read as many aviation magazines and blogs as you can, keeping an ear out for the names of companies that you had not heard of before, then go find out about these companies, their history, what they're working on... and apply! Often, you'll be able to find the email addresses (or at least the Linkedin profiles) of leaders of these companies, and message them directly with your cover letter, unlike the large aerospace companies which have layers and layers of mostly-automated HR processes trying to reject most applicants. And, like I explain below, small companies are more fun to work at, anyways...

But I'm not from the US...

Iin the US, most aerospace companies do at least some work for the US government (e.g. the military) and therefore require nearly all of their employees to have Green Cards (which makes them "US Persons" under ITAR) or to be US citizens.

That means that it is difficult - but not impossible - for a foreigner to get an aerospace job.

Firstly, don't forget that the US does not have a monopoly on aerospace. Airbus has locations all over the world (as do Boeing, BAE, etc.), Brazil has Embraer, Japan has Honda and Mitsubishi, Israel has IAI, Russia has a long list of large companies that make high-tech jets and helicopters, China also has a growing list (as do Pakistan and India and Turkey), and there are tons of countries whose aeronautical industry is small but still large enough to make, for example, their own jet trainers or turboprops or business jets or bush-planes or combat UAVs. When it comes to small single-engine piston-powered airplanes flown for fun, some of the best ones in the world are made in the Czech Republic and Slovenia and South Africa and Austria and Australia and Canada. There are also companies all over the world making small satellites, small rockets to launch them, small systems for them, and so on. And some of the most innovative work in aerospace is being done in Europe, including eVTOL airplanes and self-flying taxi multicopters, engines for high-speed/high-altitude flight that can work either as a jet or as a rocket, next-generation stealth fighters and unmanned mini stealth bombers, single-engine Very Light Jets, practical airplanes powered by hydrogen fuel cells or by solar power or by hybrid-electric engines, shaped like blended wing bodies, able to maneuver without control surfaces...

But if your goal is to come to the US... there are a few possibilities.

- One is to work in an academic setting: Apply to a Master's or PhD program and look for opportunities to get paid to do research, at least as a first step.

- Another idea is to work for companies that make small aircraft or that develop new technologies such as electric propulsion or self-flying aircraft or supersonic transports. I listed most of these companies above.

- It is also possible for foreigners to work for one of the suppliers of larger aerospace companies, e.g. the small companies that make systems or seats or galleys or engine nacelles or landing gear or fuselage structures or engine pylons for Boeing airliners and other major jets. You could then get a Green Card, and then transition to Boeing or another large company.

- Finally, one path that is very popular among foreigners is to work for a contracting company, which sends engineers to work as contractors at the larger aerospace corporations. Again, it is possible to get a Green Card this way and then transition to the larger corporation.

I'm afraid I can't offer more help than this. I have had a Green Card since I was 19, so I was already able to work for Boeing almost right from the start. You may wish to try to find someone who had to take one of the paths that I describe above.

Should I get a Master's degree?

All the large aerospace companies, and some of the small ones, will pay for at least some of your grad school, possibly all. So, I would advise that you only start working on your Master's after you get a job (maybe unless you've spent a year trying to get a job and failing).

Once you're in the industry, you'll get a much better feel for what kinds of skills and technologies are "hot", and you'll be able to make a more informed decision about what Master's program will be most effective in boosting your career. For example, when I worked at Boeing, I noticed an increasing emphasis on reducing manufacturing costs (by re-using old components, using less-expensive manufacturing processes, having suppliers compete against each other, increasing automation in the factory... and other things, which our competitors already do). So, when I looked for a Master's degree, I was looking for one that gave me as much of this knowledge as possible... at a highly-ranked school... that could be done online (because it's much easier to watch a lecture in the evening from home in your pajamas... and, most critically, to be able to pause and rewind so you get a second chance to understand the tricky parts)... and that gave me a degree that said "mechanical engineering" (not "industrial engineering" for the reasons I discussed earlier... and not "engineering management" or "engineering science", which are not really engineering, i.e. are generally not recognized as such). At the time, Columbia University had the most highly-ranked online engineering Master's programs. (It still does today; Can't go wrong with an Ivy League school!). Columbia allows up to 40% of graduate-level courses to be in a "related discipline". So I got an Ivy Leage Master's in Mechanical Engineering... and 40% of it consisted of industrial engineering courses, which gave me those skills and knowledge that helped me get more responsibility at Boeing (bigger projects and eventually a cooler job doing future airplane development) because I understood the thinking around how to design for minimal manufacturing cost.

All I'm saying is: Getting a Master's after you start working can be (A) free and (B) a more effective boost for your career.

How is work-life balance? Do you work crazy hours, weekends... or just 40 hours a week?

It depends. Even in some large companies, some projects require crazy hours and some jobs have 40-hour weeks. At some small companies... same thing. At other companies, large and small, there is a start-up culture where people who do not work 12-hour days are frowned upon (i.e. not punished, but thought of as lazy, i.e. not given the cool projects). But even in the companies that value 40-hour weeks, certain jobs - like flight-testing - will involve early mornings, late evenings, and weekends, often at remote locations.

In general, large companies - and companies that work in defense - seem to have good work-life balance, and small companies have the start-up mindset where people work lots of hours and weekends... but there are plenty of exceptions to the rule. (I currently work at a small company that has terrific work-life balance, except for maybe a couple of weeks per year when we do flight-testing and go to airshows).

In short: The only way to know for sure is to ask people who have experience in the job/company that you are considering.

Do you get to travel for work?

Like the previous question, "it depends", there is no way to know for sure unless you ask someone on that specific team. Some engineering groups travel all the time to demonstrate their products to customers, or to test whatever needs to be tested. Some engineers travel occasionally to teach. Some engineers never travel. And sometimes a single team could have a mix of all these. When I was a structures engineer specializing in fatigue, damage tolerance, and fracture mechanics, I probably traveled about three times a year (for one week each time) to teach courses about those topics, and about once a year (for about two days) to help set up a fatigue test at a new lab. However, the engineers whose desks were on either side of mine... did not teach, and were only involved with local tests, or only ever did analysis on their computers, or supported other engineers in our company via phone calls and virtual meetings, so they never had to work anywhere other than at our building. Back when I did maintenance engineering, I think I only ever traveled once, to take a one-week course, although some of my coworkers occasionally (maybe once a year) traveled to airplane maintenance shops and to accident sites.

How much work is done by yourself versus as part of a team? What is the work environment like?

This is a very important question that doesn't even occur to a lot of engineering students. This is the question that more people SHOULD ask! Read the two descriptions below and ask yourself; Which one fits my personality?

I have worked in engineering offices that were almost as quiet as a library. Whenever someone wanted to chat, they would swing by your desk and say "Let's go sit down in the atrium" (where there are comfortable seats and little tables, ideal for small meetings) or "Let's go to a privacy room" (a little room with a table and 3 or 4 chairs), so as to not disturb everyone else. Same thing to deal with phone calls. When a new project came in, it would take months to work through, so you'd get an email saying "Let's all meet about this tomorrow in the conference room", then have one or two meetings a week until the project is over. Usually, big changes / big surprises / big decisions (etc.) could wait until this meeting, but if not, then we'd set up a meeting for later this afternoon or tomorrow morning if something was really urgent. For the most part, people sat quietly at their desks, and had a chance to prepare to deal with questions or decisions.

I have worked in engineering offices that were as loud as a party. That's an exaggeration, but there was always someone talking. You might be at your desk in the middle of something, but someone would walk right up to you and say: "Quick question" followed by a complicated problem that was not quick at all... and many of them would not even start with "Do you have a minute or shall I come back later?". People took phone calls from their desks, even dialed into virtual meetings from their desks rather than from meeting rooms. When a new project came in, it was expected to take maybe a week, so someone would walk right up to you and say "I don't have time to write an email, but: Something came up. Let's go find So-and-So and Joe Schmoe so that we can figure out what to do". Sometimes big decisions were made when one person was chatting with another person at their desk or by the microwave, and the rest of the team might not even find out right away. Sometimes it was someone walking up to you and saying "I think we should solve this problem this way, and we're going to move forward with that unless you can tell me right now why the alternative is definitely better or if I'm missing some giant risk". No preparation, seat of your pants. It was like an episode of "The West Wing".

For most people, one of the two descriptions above sounds like a nightmare. (You may have been able to tell that my blood pressure got uncomfortably high just from writing the second one). So, while interviewing for a job, you should try to find out which one you're applying for. I have seen both extremes within a single company! (My current job is somewhere in the middle).

How hands-on is your work? How much creativity is involved? Are you very specialized or do a little bit of everything? How does early-career work differ from late-career work?

It depends. In a small company, you're more hands-on, use more creativity, do a little bit of everything, and typically get to have a hand in decisions that impact the product. In large companies, you're less hands-on, use less creativity, do a narrower and more specialized kind of work, and typically do more boring "grunt work" for a few years before you have the responsibility to help make decisions that impact the product. More details below.

What are the differences between working at a large company vs. working at a small company? Which would you recommend?

I've recently quit my job at a giant company (Boeing Commercial Airplanes: ~150,000 people, ~40,000 engineers) to go work at a tiny company (Van's Aircraft: ~80 people, ~7 engineers) and the differences were even greater than I expected.

In the previous question, I laid out what I think are the biggest differences:

- In a small company, everyone does everything. In a large company, people have more specialized jobs. (The way I think about this: One way to get people to get really good at what they do is to have each person only do a narrow set of things. This goes back to Henry Ford and the assembly line). Over the life of an airplane, you need different kinds of engineers at different times: preliminary design, aerodynamics, structures architecture, manufacturing, systems, detail design and analysis, testing, certification, customization for customers, maintenance... all happen at different points in the process. (They almost all happen at least a little bit all the time, but there are short periods when they happen a lot). So it's possible for most of the preliminary design people to be working on whatever project is newest, for most of the aerodynamics people to be working on whatever is the second-newest, for the structures architecture people to be mostly involved in whatever is the third-newest, and so on. If there is a new project every couple of years, then everyone can always work on their specialty. But if there is only one project every 5 years, and each project is less complex and only requires a few engineers in total (as is the case in small companies) then each engineer will have to perform all those roles (and will never get as good as any of them as a dedicated expert at a big company). From an engineer's perspective, this has pros and cons. The pro is that it's more fun to do more kinds of things. One disadvantage is that a company is only really able to develop new technologies - to develop an airplane whose efficiency, or speed, or maneuverability, or whatever, is superior to any other in history - if their engineers are experts. This is why large companies develop the most technologically advanced airplanes in the world. Do you think it would be better to contribute 0.1% of the most technologically advanced airplane ever... or to contribute 15% to the design of an airplane that is cool and popular and fun but not groundbreaking or as efficient as it could be if it had been more thoroughly analyzed? Different people may answer that question differently. I will say this: Within my first couple of months at Van's Aircraft, I looked at the work that I had done and I could count about twenty different job functions at Boeing that would be required to do all those kinds of work, from engineers doing structural design and analysis, to technicians running tests or maintaining airplanes, to "bean counters" doing supplier management and tracking quality issues.

- In a large company, because lots of people are dedicated to a single job and do it all day every day for years, it's worth documenting step-by-step processes for how to do that job well, like pilot checklists, but for doing various kinds of engineering analysis: Structural, aerodynamics, systems, etc. Sometimes it's even worth creating software (or at least Excel spreadsheets) to lead engineers through the required steps in the order that works the best. That way, people are more likely to do the job right, as well as possible, and to avoid pitfalls. Unfortunately, this means there is less room for creativity. Sure, sometimes an engineer thinks of a better way to do the analysis, or of a way to make the analysis software more intuitive or more accurate for more general cases... but, in general, it can feel a lot like cooking from a recipe. In a smaller company, there is a lot of "Ok, now we're [doing X]. Let's figure out how to do it!". The previous person who did it may have a few pointers, but there will be much less guidance than at a large company. Like with the previous point, this means that the work will end up being done slightly less efficiently, and maybe slightly less effectively, than it would be humanly possible... but the engineer will get to figure it out and be creative, which is more fun, rather than being handed a long list of steps and having only to look up what each of the terms mean and where certain bits of information can be found. On the other hand, sometimes being handed a list of steps is a lot less stressful than being told "Figure it out, good luck"!

- In a large company, most engineers do not do a lot of hands-on work, e.g. prototyping new parts or physically setting up and running tests, let alone manufacturing components or assembling big chunks of airplanes or fixing broken ones. That is because technicians/mechanics/machinists are able to do all this, and they cost a lot less per hour, so it's less expensive overall to have them doing all the things that they can do while the engineers do the things that only engineers can do. Of course, as with specialization: At a small company that does not have every kind of work going on all the time, it's not worth having multiple crews of technicians/mechanics/machinists, one crew for each kind of thing that these jobs can entail; It may be worth having engineers that (at least between them) can do all those things (even if slightly more expensively). So, at a small company, engineers end up occasionally fabricating stuff, putting together the test set-up, and sometimes even building and maintaining airplanes, when those things are required and the technicians/mechanics/machinists are busy doing something more urgent.